AMAZON multi-meters discounts AMAZON oscilloscope discounts

The rotor in an AC motor can be constructed from coils of wire wound on laminated steel or it can be made entirely from laminated steel without any wire coils. A rotor with wire coils is called a wound rotor and it's used in a wound-rotor motor. The wound-rotor motor was popular in the 1950s since it could produce more torque than a similar-size induction motor. The main drawback of the wound-rotor motor is that it requires the use of brushes and slip rings to transfer current to it. Since modern AC induction motors can now produce adequate torque, the wound-rotor motor is not often used because the brushes and slip rings require too much maintenance.

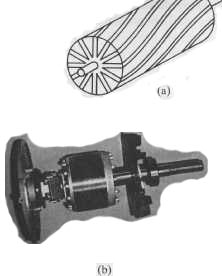

Motors that use a laminated steel rotor are called induction motors or squirrel cage induction motors. The core of the rotor is made of die-cast aluminum in the shape of a squirrel cage. Laminated sections are pressed onto this core or the core is molded into laminated sections when the squirrel-cage rotor is manufactured. Fig. 1 shows a diagram and picture of a squirrel-cage rotor and notice the skeleton of the squirrel-cage core. The fins or blades are built into the rotor for cooling the motor and it's important that these fan blades are not damaged or broken, since they provide all of the cooling air for the motor and they are balanced so that the rotor will spin evenly without vibrations.

Above: Fig. 1: (a) Diagram of a squirrel- cage rotor for an AC motor.

(b) Picture of a squirrel-cage rotor for an AC motor.